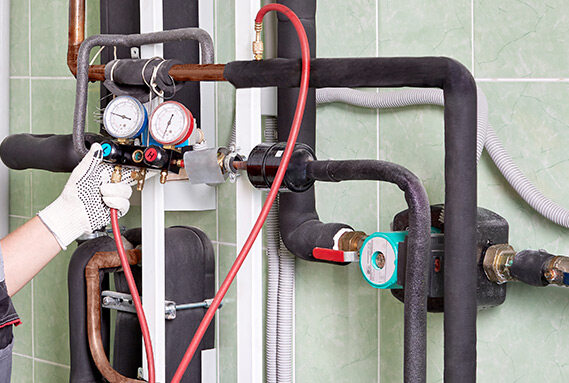

Commercial Boiler Repair and Replacement

Check-up and Maintenance

Get Your Questions Answered

Save on Energy Bills

The Valley Comfort Commercial Heating & Air Difference

Experienced

Our staff is equipped to give outstanding maintenance, installation and repair services for commercial boiler systems.

Available

We look to serve our customers any day, any time. Our factory-trained technicans are happy to answerany questions you may have, 24/7.

Reliable

We are a family-owned company, serving residential and business owners with the utmost honesty and integrity.

Locations We Serve

Sonoma County

- Cotati

- Healdsburg

- Petaluma

- Rohnert Park

- Santa Rosa

- Sebastopol

- Sonoma

- Windsor

Napa County

- American Canyon

- Calistoga

- Napa

- Oakville

- Rutherford

- St Helena

- Union

- Yountville

Marin County

- Novato

- San Rafael

Commercial Boiler Systems and Installation

The importance of adequate heating and cooling, especially in very large buildings, is hard to overstate. The interior climate of a building is about comfort, but it is about more than that, too. When everyone inside feels comfortable and isn’t concerned with the temperature, it is easier to remain focused while staying productive.

For some structures, traditional HVAC technology is sufficient to meet the needs of a building. When it comes to heating, that means furnaces that use natural gas or fuel oil to heat air directly via combustion. For very large buildings and many older structures, however, these solutions may prove too expensive and too inefficient for your needs.

Boilers are some of the oldest types of heating solutions. Still, modern versions continue to deliver reliable heating and hot water solutions to buildings throughout California and indeed across the entire USA. These systems are not as common as they once were, and as a result, many people do not have as clear an understanding of how they work as they do furnaces or air conditioners.

Are boilers the right solution for your building? If you already have an existing boiler setup, how could it be improved, and what can you do to keep it functioning well year after year? While boilers can seem a daunting subject when you first start exploring your options, they could represent the most cost-effective heating solution available for your building.

Let’s dive into this technology and explore the answers to many common questions about commercial boiler installation and maintenance. Rely on this guide to provide the overview you need to get started and build a strong understanding to use for purchasing the best boilers for your business.

Table Of Contents

Types of Commercial Boilers Available Today

Fire-tube Boilers

Fire-tube boilers have a long history and were one of the most popular options for decades. In a fire-tube boiler, the burning source of fuel does not heat water directly. Instead, the hot gasses from the fire travel through tubes surrounded by water. These metal tubes then transfer the heat of the gas directly to the water, heating the liquid and creating steam.

When should you choose a fire-tube boiler? If your business has an additional demand for steam alongside heating needs, they may be ideal. However, maintenance on fire-tube boilers can be costly, difficult, and frequent, and they aren’t suitable for applications involving high steam pressures.

Water-tube Boilers

Perhaps one of the most common types of boilers today, the water-tube type reverses the setup from a fire-tube boiler. In this application, the burning fuel directly heats metal tubes filled with water. Water-tube boilers can achieve millions of BTUs in thermal output and are typically the most likely candidates for heating larger buildings and offices.

Water-tube boilers have a good reputation for efficiency and responsiveness, as they can more quickly provide rapid heat output and adapt to differing demand loads. They are also safer and easier to maintain than fire-tube boilers.

Electric Boilers

Although electrically powered boilers are a small segment of the market, they remain a potential choice for those in Napa looking for boilers. Instead of using any fuel for combustion, these boilers use electric resistance to heat water and generate steam. They are extremely quiet, compact, and environmentally friendly. However, electric boilers may not be as suited to providing the heat necessary in high-demand applications, and they may be more expensive to run when compared to natural gas or oil-fired boilers due to high electricity costs.

Find out What Commercial Boiler Works for

You by Connecting with Our Technicans

Boiler Maintenance & Service

As complex pieces of equipment, boilers require careful attention and periodic maintenance to keep them efficient and operating safely. While ideally you should not need frequent commercial boiler maintenance, it is always a good idea to know what to look for and how to prevent unwanted problems from occurring. Here are some important fast facts.

Common Boiler Concerns

Some of the most typical problems you may encounter with a boiler include:

- Leaking pipes or boiler housings

- No or little heat output despite apparent boiler operation

- Noisy operation

- Low chamber pressures

How Can I Avoid a Boiler Failure or Service Disruption?

Annual service and routine preventative maintenance are the keys to keeping your boiler in good working order. Read on for more information in our FAQ about service intervals.

How Much Does Boiler Maintenance Cost?

The answer varies based on the type of boiler you have, its age, and the severity of any problems uncovered. A typical annual maintenance visit may cost several hundred dollars, and is typically more expensive than furnace maintenance. However, the cost is small compared to replacing a unit that fails because of missed maintenance. The right provider can make service a cost-effective investment.

How Should I Select a Boiler Contractor?

Look for experience, trustworthiness, and proof of credentials. Seek out maintenance providers with a good reputation in the commercial community and a proven record of reliable service. Always ask to see licenses and insurance information to protect your business. Because of the specialized nature of boilers, it is a good idea to choose a team with an extensive background in commercial boiler repair.

Efficiency in Boiler Operations

While boilers supply consistent and steady heating while enabling other applications in the business too, cost is always a concern in commercial applications. As a result, efficiency is a major concern when it comes to boilers. How well can your boiler take the fuel you pay for and convert it into heating energy your business can use? Let’s take a quick look at what to know about boiler efficiencies.

How We Measure Boiler Efficiency

The most common acronym you’ll encounter when looking at boilers is “AFUE,” which stands for annual fuel utilization efficiency. AFUE is a basic yet very helpful measurement of how well a boiler uses its fuel source. For example, in an electric boiler, its AFUE rating might be near 100% because of the very seamless transfer of energy in electrical applications. In old boilers, you might see an AFUE as low as 80%. With modern advances, an AFUE of about 90% or more is common.

What does all that mean? In the last example, with an AFUE value of 90, you could expect the boiler to make use of 90% of all the heat energy it generates. The remaining amount escapes to the atmosphere as a natural loss.

Making Your Boiler As Efficient As Possible

The best way to ensure your boiler is cost-effective is to select the appropriate unit at the time of installation, sized to provide enough heating output to supply your building adequately. In most cases, older units should undergo replacement with new, higher-efficiency condensing boilers, both for safety and effectiveness purposes. Regular maintenance to keep your boiler in good shape and operating as designed is also imperative.

The Most Common Commercial Boiler

Which boiler solution is best for your business? There is no “one size fits all” answer to that question, and in reality, it is difficult to know whether fire-tube or water-tube boilers are most common. Ultimately, boilers are not like air conditioners or furnaces; the right solution will always vary, so opting for the most common option is not necessarily the best choice.

Commercial Boiler

Only a qualified Sonoma County boiler company can make a smart suggestion for which tube-type to opt for when replacing or installing a boiler. However, there is one functionality that is common to commercial boilers that buyers should look for — a condensing feature. Condensing furnaces, both water- and fire-tube types, are the most common and popular solution in Marin for boilers.

Efficiency

What makes condensing boilers so popular? Efficiency.

As we’ve explored, cost-effectiveness is an important factor for users of commercial boiler equipment. A typical boiler will only be able to achieve an efficiency rating of about 80%, meaning there are substantial losses that equate to wasted fuel and money. However, new units that feature special “condensers” have changed the game. With a condensing boiler, it is possible to achieve efficiency ratings of 90 to 95% — and perhaps even higher. How?

Today’s Boilers Can Achieve Efficiency Between 90 and 98.5% Consistently.

In standard boilers, the exhaust gases escape through a vent after heating the water. With a condensing unit, the gases from the boiler flue cool just enough to allow water vapor to condense. The boiler captures this heat from the condensation and feeds it back into the boiling cycle. Not only does a condensing unit reduce emissions, but it is also highly cost-effective.

Condensing units do have some drawbacks. They are often more expensive than non-condensing counterparts. However, considering the potential energy savings, these units typically pay for themselves over time. As a result, they remain the most common and popular choice for commercial boilers today.

Boiler System Placement Considerations

Choosing a boiler is a challenging step on its own, but where will you place it when it arrives? Most buildings equipped to user boiler technology often have purpose-built boiler rooms, but locating your unit may prove challenging without a dedicated space. Some commercial boilers are quite large, and their imposing footprint makes good decision-making during the planning phase a must. What are some of the things to consider about placing a boiler within your building?

Heating System Placement: What to Consider

Noise

Boilers are typically quiet, but gas furnaces are known for their wide variety of sounds. In forced air systems and with heat pumps, the sound of the blower and extractor fans can prove a frustrating distraction.

Access

When considering unit placement, think about ease of access for service professionals in the future. Don’t place a unit somewhere that would make maintenance difficult, it can prove costly and challenging to work on the unit.

Space Requirements

Furnaces and boilers aren’t small; they need specific areas dedicated to their function. It’s especially true for furnaces which require a sufficient volume of air to draw upon for combustion. Carefully calculate space requirements and evaluate suitable spaces in the building with the help of your contractor.

Energy Efficiency

Consider the potential effects on efficiency based on placement. For example, a boiler placed too far away from most of the radiators will not yield the best results. Likewise, a furnace put in a space that is too small will struggle to consume fuel fully, leading to unnecessary exhaust and inefficiency.

Climate

Yes, even the climate outdoors can affect your system and should be a consideration when placing a new unit. For example, package units which reside outdoors or on the roof of your building may be susceptible to snow or icing conditions during very cold conditions. Low temperatures can have a deleterious effect both on the equipment and its ability to operate.

The History of Commercial Boilers

At its most basic, a boiler is simple to understand. It involves heating water inside of a heavy-duty closed container, sometimes under pressure, to temperatures near and even beyond boiling. The hot water or steam that results from the burning of fuel in the boiler can then circulate throughout the building, allowing the natural radiation of heat to warm spaces evenly and thoroughly. The most common types of heating applications with boilers include traditional radiators, baseboard heaters, and even under-floor tubing for heat transfer.

Compared to air conditioners and modern furnaces, boilers are relatively old technology, with a long history. Modern boilers first appeared about 150 years ago. Let’s take a quick trek back in time to explore the development of the boiler technologies that gave us the systems we know and use today.

The early 1800s

Near the end of the 18th century, a type of boiler known as a “kettle system” was invented. In kettle boilers, water sat above a firebox and was heated directly by the flames, turning the water to steam. These systems drew upon early boiler experiments going as far back as the 1650s, but it was not until the Industrial Revolution that boilers grew into their own. Early boilers were primarily used for steam power, not heating, and drove the rise of the steam locomotive using powerful boilers.

The mid 1800s

Innovation by two American inventors, named Stephen Wilcox and George Babcock, led to the first breakthrough in boiler technology in decades. This safer type of boiler, though inefficient, allowed for the creation of much more steam. Across the Atlantic Ocean, the heating radiator was invented in 1855 by Franz San Galli. Together, the boiler and the radiator allowed for indoor heating on a scale not yet seen before.

The late 1800s

Cast iron radiators begin to proliferate thanks to their safety and better efficiency as boiler technology grew more advanced. More boiler-building companies appeared, and indoor heating driven by boilers begins to take hold, replacing older methods of heating such as wood fires.

The early 1900s

By the 20th century, boilers could generate huge amounts of steam and hot water on an hourly basis. Radiators and commercial boilers for whole-structure heating were now commonplace across the country. As demand increases, more research and development efforts pour into making boilers more efficient than ever.

The late 1900s

Residential boilers appear and provide options for in-home heating once only available to commercial consumers. Advances in materials science and boiler design continue, developing extremely high efficiencies and making boilers one of the best solutions for large-scale heating. These innovations continue into the 21st century, and boilers show no signs of going away any time soon.

FAQs

What Size Boiler Do I Need?

One common rule of thumb used in the industry is to add 50 BTU for every square foot of space in the building. Naturally, this leads to very high BTU requirements for commercial spaces. Speak to a boiler contractor about conducting a thermal assessment on your building to determine how many BTUs you require for adequate heating.

How Long Do Boilers Last?

Boilers are quite rugged compared to other heating technologies, and commercial units even more so. A typical baseline expectation is about 15 years, but high-quality industrial units may last many decades when appropriately maintained.

How Long Does It Take to Install a Boiler?

Not counting the time necessary for acquisition and shipment of the appropriately sized boiler, it will usually take a few days to complete a brand new boiler installation. Time estimates may vary based on job conditions.

How Often Should I Receive Boiler Service?

Aim for a complete service visit approximately once a year. For buildings that put boilers to work under heavy loads regularly, a visit once every six months may be appropriate to catch any potential faults early. Prevention is always cheaper than repair!

Valley Comfort Commercial Boilers

Valley Comfort Heating and Air is a family-owned business providing boiler services to Napa, Sonoma, and Marin Counties. With extensive capabilities, we’re fully equipped and able to supply cutting-edge commercial boiler systems for businesses both small and large. Whether you need the latest in high-efficiency boiler technology or a repair for an old workhorse system, we provide value, helpful insight, and trustworthy service from start to finish to deliver the best return on your investment.

Request a Consultation

Please complete this form:

We serve Residential and Commercial customers in the following counties and cities

Sonoma County

- Cotati

- Healdsburg

- Petaluma

- Rohnert Park

- Santa Rosa

- Sebastopol

- Sonoma

- Windsor

Napa County

- American Canyon

- Calistoga

- Napa

- Oakville

- Rutherford

- St Helena

- Union

- Yountville

Marin County

- Novato

- San Rafael